An email exchange with a gentleman in Sweden began with the following note:

Subject: Riehle 50-ton machine still in use

Sent: Tuesday, February 10, 2004 8:39 AM

From: Gustafsson Lars [lars_e.gustafsson [at] scania.com]Hello!

In the Strength and Durability Lab of the heavy truck company Scania in Sweden, there is still a Riehle Universal Testing Machine in use. I have seen it there every work day since 1964, when I started as a young test engineer at Scania. The machine arrived in Scania in 1914 and at that time it was manually driven. The machine identity card says it was equipped with an electric motor in 1918. (still in place) I wonder what this manual actuation system looked like? Do you have a picture that shows it?

Best Regards

Lars Gustafsson

Senior Engineer, Strength and Reliability

Truck Development

SCANIA

SE-151 87 Södertälje, Sweden

Despite our inability to help him with his questions, Lars agreed to provide pictures of the device and followed up with an explanation of how these testing devices work. Our thanks to him for the following information and pictures:

From: Gustafsson Lars

Sent: Friday, February 13, 2004 5:34 AM

Subject: VB: Pictures of Scania RiehleHello Nick!

The machine works like this:The electric motor to the right is connected to the two big vertical screws via a four speed gearbox. When the motor is running, the screws will rotate and the orange crosshead will move up or down, depending on the rotation direction of the motor. If the test object is placed on the table it will be compressed, and if it is connected between the upper crossbeam and the moving crosshead it will be stretched.

The whole table is resting on edges and connected to the measuring arm via several levers. The general idea is the same as for your grandma’s kitchen scale. When a downward load is put on the table the balance arm moves upwards. By turning the wheel you can move the weight out along the balance arm until the arm just begins to move down again. Then the system is in balance and you can read the tons on the scale along the arm, and the kilograms in the small rectangular window close to the wheel.

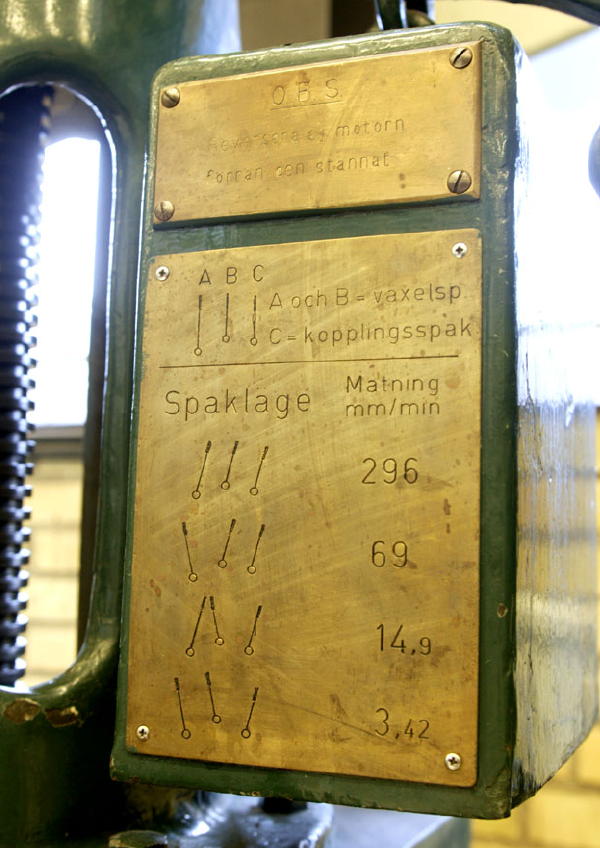

The brass plate describes the settings for the gearbox. A and B are levers for selecting speed, and the lever C is for the clutch. Speeds are in millimeters per minute, that is 14,9 is about 1/2 inch/minute. If you need a high force you have to use the lowest speed and if you want to move the crosshead quickly (unloaded) to another position, you choose the highest speed.

The machine has recently been used to test energy absorbing structures to be placed in the front of the truck. It has also been used for leaf spring static tests. It can also be used just as a solid and stable “force generator” for a number of simple and quick static tests.

If you have more questions, you are most welcome!

Regards

Lars

Thanks for your contribution, Lars. If anyone can provide the information Lars requested above or has other information on Riehle Brothers, please contact us.

If you find this topic interesting and would like to share with family on

social media, please click below and spread the word.